Waterborne Polyurethane and Matting Technology

Waterborne polyurethane, which exists as aqueous solutions, dispersions, or emulsions of polyurethane resin in water, is widely used in decorative coating applications across various fields such as construction, home furnishings, automotive, leather apparel, and household appliances. In specific scenarios where low-gloss or matte waterborne polyurethane coatings are required, matting technology becomes particularly important.

△ Methods for Achieving Matting Effects

Currently, matting effects in coatings are primarily achieved through two approaches: adding matting agents or modifying the resin to be self-matting. However, relying solely on matting agents, while effective in reducing gloss, can lead to issues such as sedimentation of the matting agent, reduced emulsion stability, and uneven gloss due to poor dispersion. Therefore, self-matting resins that do not require external matting agents and microsphere-type waterborne polyurethane matting resins are gaining increasing attention.

△ Principle of Adding Matting Agents

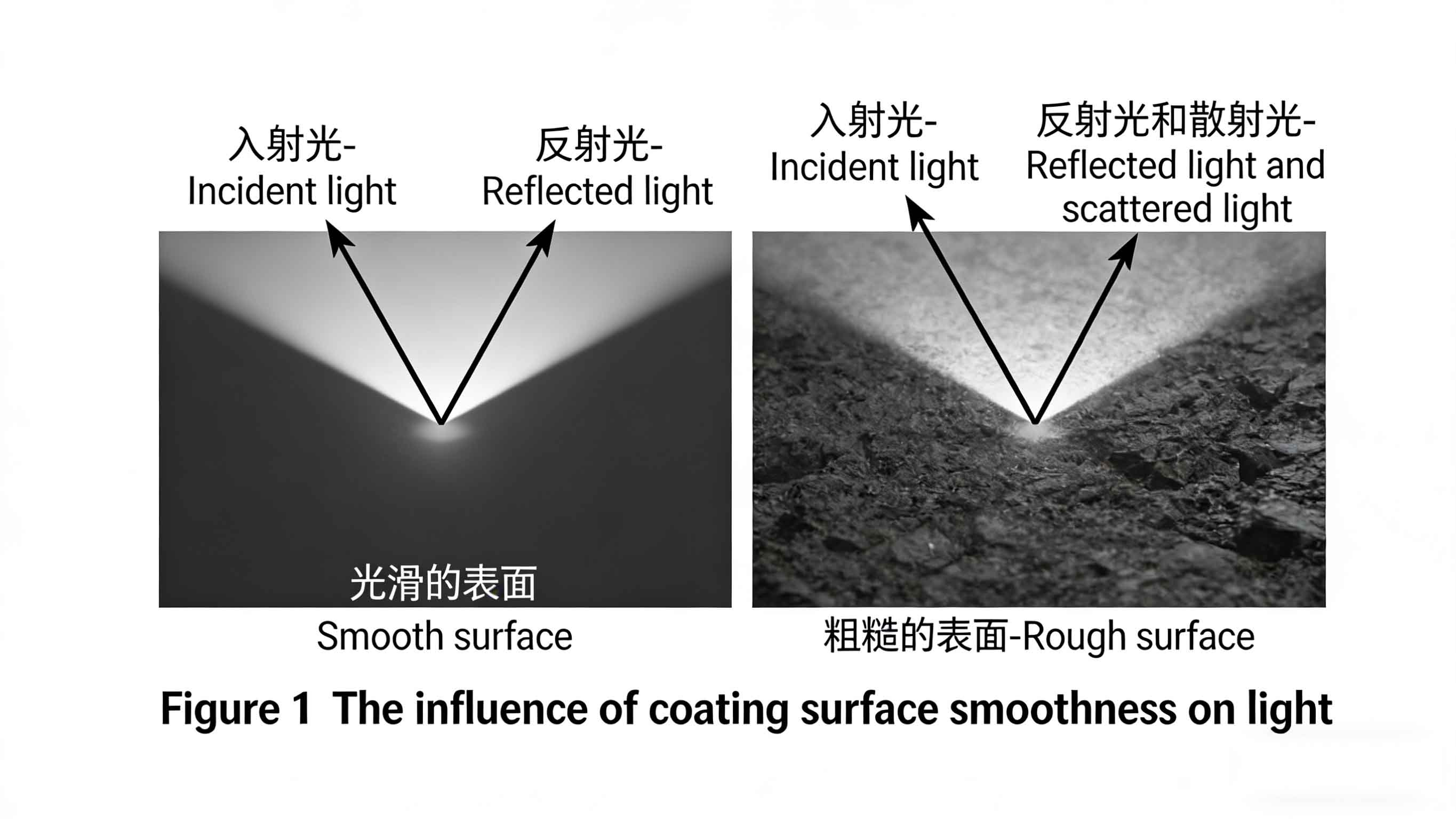

So, what is matting? Its core lies in creating a microscopically rough surface on the coating film. When light strikes this uneven surface, diffuse reflection occurs, reducing specular reflection and scattering light in various directions, ultimately achieving a matte effect. This phenomenon of light reflection on object surfaces is illustrated in Figure 1. Matting agents function as a physical method to alter the gloss of coatings. As water evaporates during the drying process, the matting agent migrates to the surface, creating microscopic irregularities that increase surface roughness and thereby diminish specular reflection.

△ Types of Silica Matting Agents

Common matting agents include metal soaps, polymer waxes, talc, and silica (SiO₂). However, metal soaps and polymer waxes may float on the surface of the solution, leading to uneven gloss in the coating film, while their dispersibility and compatibility in waterborne resins are often poor, potentially causing demulsification or gelation. In contrast, silica, as an inorganic compound, offers advantages such as ease of modification and excellent dispersibility in waterborne polyurethane systems. Silica matting agents include fumed silica, precipitated silica, and silica aerogel. Fumed silica, an ultrafine powder with surface hydroxyl groups and adsorbed water, stands out for its small particle size, large specific surface area, and high surface activity. Precipitated silica, a white amorphous hydrated silicic acid powder with spherical particles bearing various hydroxyl groups, exhibits excellent performance, simple production processes, low energy consumption, and broader applications compared to fumed silica. Silica aerogel, a lightweight nanoscale porous gel solid material, is notable for its superior structure, large specific surface area, high pore volume, narrow pore size distribution, and good transparency.

△ Principle of Chemically Matte Polyurethane

Matting can also be achieved through chemical methods, where light-absorbing compounds are introduced into the coating resin via chemical reactions to alter the optical properties of the coating film. Self-matting resins refer to coating resins that produce a matte surface upon film formation without adding external matting powders or waxes. Their components exhibit physicochemical properties and functional groups similar to matting agent particles, ensuring good compatibility and consistent refractive indices when blended with other resins, effectively addressing issues associated with external matting agents. Moreover, since external matting agents often differ in refractive index from the coating matrix, it is challenging to balance matting and transparency, limiting their suitability for certain applications. Therefore, self-matting coating resins that do not rely on external matting agents have attracted widespread attention. Their matting mechanism primarily involves introducing incompatible particles during polymer synthesis, such as through organic silicon modification or crosslinking modification. For example, in organic silicon-modified waterborne polyurethane matting resins, hydrophobic silicone segments migrate to the coating film surface during film formation, creating a microscopically rough surface. This imparts both organic and inorganic characteristics to the polyurethane, effectively enhancing its water resistance, thermal stability, and mechanical properties. Crosslinking modification alters the linear polyurethane structure, forming a densely crosslinked network of polyurethane macromolecules. This increases the particle size of the polyurethane emulsion, and during drying, the larger particles stack to form a rough surface. Additionally, the dense crosslinked network significantly improves the heat resistance, water resistance, and chemical resistance of the waterborne polyurethane.

Researchers have successfully prepared internally crosslinked modified waterborne polyurethane self-matting resin emulsions using a post-chain extension method. The resulting films exhibit rough surface characteristics. Under varying crosslinker addition levels (0.35%, 0.45%, 0.55%, and 0.65%), scanning electron microscope (SEM) images of the films are shown in Figure 2, labeled as stages a, b, c, and d, respectively. These emulsions have an average particle size exceeding 1 μm and a gloss level of approximately 2.0 at a 60° angle, fully meeting matting requirements.

Development Prospects of Self-Matting Resins

△ Advantages of Self-Matting Resins

Matte coating resins play a critical role in the application of waterborne polyurethane resins, attracting significant attention from the coatings industry while posing challenges in terms of stability. However, the emergence of self-matting coating resins and microsphere matting coating resins, which require no external matting agents and offer excellent resin stability and superior coating performance, indicates they will become a dominant trend in the future.

△ Future Development Trends

Therefore, it is essential to intensify research and development efforts on waterborne polyurethane matting resins to promote their broader advancement. Developing self-matting coating resins will be a key focus for the future of waterborne polyurethane.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :